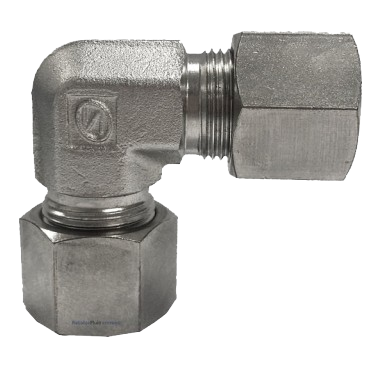

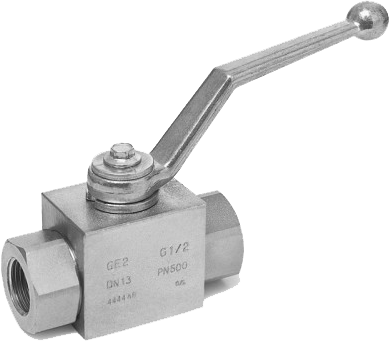

In order to manage the fluid in hydraulic systems, hydraulic ball valves are often a type of unique carbon steel or stainless steel ball valves utilized in the hydraulic sector.

The ball valve at high-pressure can rotate in a full 360 degrees. With a circular through hole or passage through the axis, the plug body is shaped like a spherical. The primary functions of a ball valve in a pipeline are to distribute, stop, and alter the medium's flow direction.

To close the tight, a modest rotating torque is required and it only needs to revolve 90 degrees. Although recent advancements have allowed for the construction of ball valves with throttling and flow control, such as V-ball valves, they are still best suited for usage as switches or shut-off valves.

The primary attributes of a high-pressure ball valve include its small size, dependable sealing, straightforward construction, easy upkeep, sealing surface and spherical surface that are frequently in the closed state, resistant to medium erosion, simplicity in operation and maintenance, and compatibility with a variety of media including water, solvent, acid, and natural gas. Many businesses have made extensive use of working media, as well as bad media working conditions, such as oxygen, hydrogen peroxide, methane, and ethylene. There are two types of ball valve bodies: integral and modular.

Hydraulic Fittings Manufacturer & Supplier in Tamil Nadu